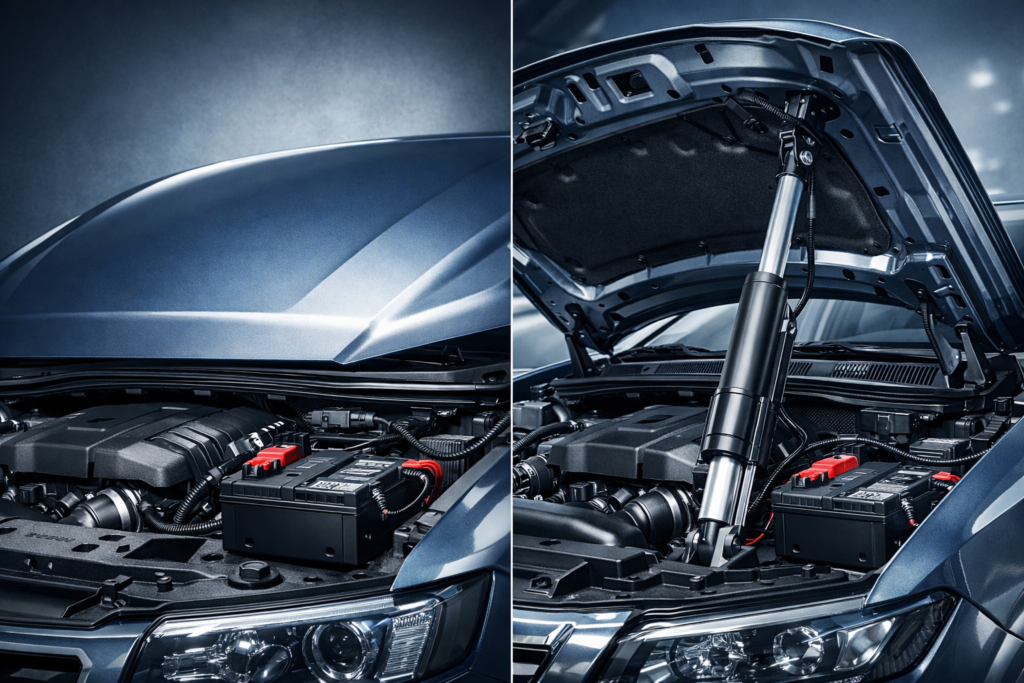

Opening and closing an engine hood may look simple, but in many vehicles and machines—especially heavy-duty equipment—it can be physically demanding, time-consuming, and even unsafe. This is where engine hood open & close systems using electric actuator come into play. By replacing manual lifting or traditional gas springs, electric actuators bring automation, precision, and safety to engine access.

From heavy machinery and commercial vehicles to custom cars and modern automotive projects, electric actuator–based hood systems are becoming the preferred solution for convenience and reliability.

What Is an Engine Hood Actuator?

An engine hood actuator is a powered linear motion device that automatically opens and closes the engine hood using electric or hydraulic power. Instead of manual lifting, the actuator provides controlled movement at the press of a button.

- Electric actuators run on the vehicle’s battery and use an electric motor to extend or retract.

- Hydraulic actuators use pressurized fluid to generate force, commonly seen in very heavy hoods or industrial machinery.

Both systems offer smooth operation and stable support, but electric actuators are increasingly popular due to their simplicity, efficiency, and ease of integration.

How an Engine Hood Actuator System Works

Electric Actuator–Based Hood Operation

Electric actuators use a DC motor powered by the vehicle battery. When activated through a switch or control module:

- The motor drives a lead screw or gear mechanism.

- The actuator rod extends or retracts.

- This movement lifts or lowers the engine hood smoothly.

- Once fully open or closed, the actuator holds the hood securely in position.

In many designs, electric actuators eliminate the need for secondary latches, as they can lock the hood firmly when closed.

Hydraulic Actuator–Based Hood Operation

Hydraulic systems rely on pressurized fluid to move the hood.

- A pump generates pressure.

- Fluid flows into a hydraulic cylinder.

- The piston moves to lift or close the hood.

- Accumulators may be used to allow operation even when the engine is off.

Hydraulic actuators are typically used in very heavy-duty machinery where extremely high lifting force is required.

Why Electric Actuator Are a Smarter Choice for Engine Hoods

Key Advantages of Electric Actuator–Driven Hood Systems

Electric actuators offer several compelling benefits that make them ideal for engine hood automation:

1. Push-Button Convenience

Heavy engine hoods can be opened or closed with a single button press, reducing physical effort and saving time during inspections and maintenance.

2. Enhanced Safety & Stability

Electric actuators provide stable, controlled support, preventing accidental hood drops. This significantly improves safety for technicians working under the hood.

3. Reliable & Long-Lasting Performance

Compared to gas springs that weaken over time, electro mechanical actuators offer longer service life and consistent performance—even without the engine running.

4. Smooth & Controlled Motion

The actuator ensures steady opening and closing, avoiding sudden jerks or slams that can damage hinges or panels.

5. Easy Customization & Integration

Electric hood actuators can be integrated with:

- Dashboard switches

- Remote controls

- Key fobs

- Smart vehicle control systems

This makes them perfect for custom vehicles and modern automation projects.

Common Applications of Engine Hood Actuators

Heavy Machinery & Industrial Vehicles

In excavators, dumpers, loaders, and generators, engine hoods are large and heavy. Electric actuators make routine maintenance faster and safer by allowing effortless access.

Commercial & Utility Vehicles

Trucks, buses, and service vehicles benefit from automated hood systems that reduce downtime and operator fatigue.

Custom Cars & Hot Rods

In classic cars, hot rods, and show vehicles, electric hood actuators add a premium, futuristic touch while maintaining a clean, latch-free design.

Special-Purpose & Off-Road Vehicles

Military, agricultural, and off-road vehicles often use actuators for durability and ease of operation in tough environments.

Key Components of an Engine Hood Actuator System

A complete engine hood open & close system typically includes the following components:

1. Electric Actuator

The core unit consisting of:

- Electric motor

- Gear mechanism

- Piston/rod assembly

It generates the force required to lift and hold the hood.

2. Control Module

The controller processes input signals (from a button or remote) and directs the actuator to extend or retract at the right time.

3. Mounting Brackets

Custom or pre-fabricated brackets securely attach the actuator to:

- The vehicle chassis

- The engine hood

Proper mounting ensures smooth motion and long-term reliability.

4. Power Source

Most electric hood actuators are powered directly from the vehicle’s battery, ensuring operation even when the engine is not running.

Electric vs Manual Hood Systems: A Clear Upgrade

| Feature | Manual Hood | Electric Actuator Hood |

|---|---|---|

| Effort Required | High | Minimal |

| Safety | Risk of accidental closure | Stable & secure |

| Operation | Manual lifting | Push-button |

| Customization | Limited | High |

| Maintenance Comfort | Low | High |

Conclusion

An engine hood open & close system using an electric actuator transforms a basic mechanical task into a smart, automated function. By offering convenience, safety, reliability, and customization, electric actuators are redefining how engine compartments are accessed across industries.

Whether you’re upgrading heavy machinery, designing a custom vehicle, or improving maintenance safety, electric actuator–based hood systems provide a future-ready solution that combines engineering precision with everyday practicality.

If you’re looking to modernize your engine hood operation, electric actuators are no longer a luxury—they’re a smart necessity.