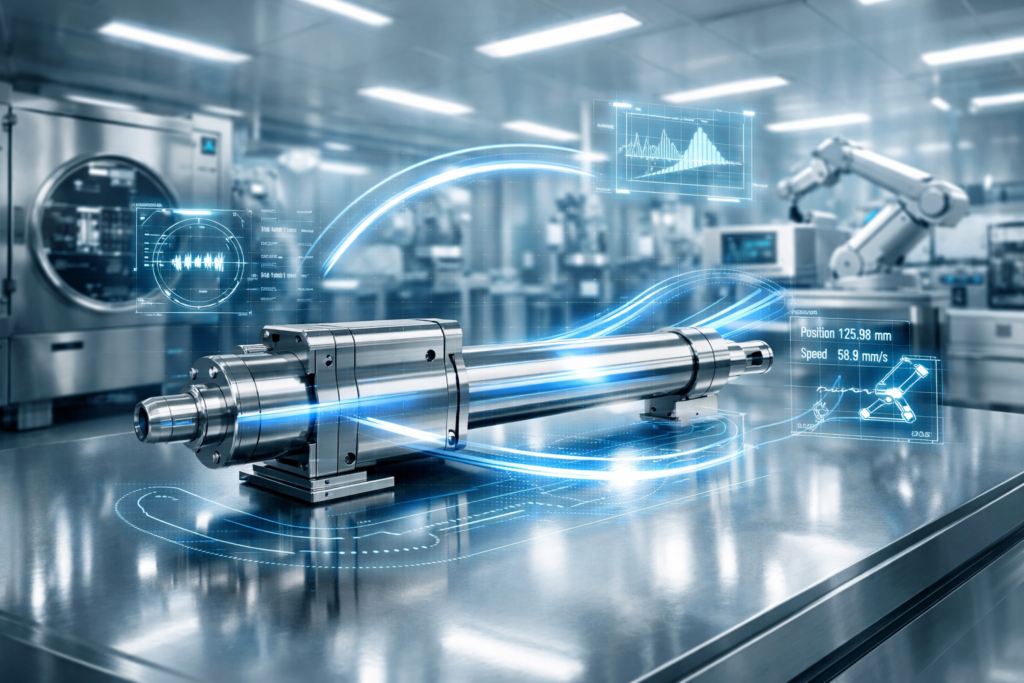

Sterile equipment manufacturing needs clean and accurate motion. Because of this, manufacturers choose automation very carefully. Linear actuator play a key role here. They move parts in a straight line. For example, they push, pull, lift, or position components. Most importantly, they work without oil. Therefore, they help keep the environment clean. As a result, many sterile industries rely on them.

Why Linear Actuator Matter in Sterile Fabrication

Sterile areas demand strict control.

Any contamination can cause failure.

Electric linear actuators solve this problem.

They operate cleanly and quietly.

Moreover, they deliver exact movement every time.

In addition, they fit into compact machines.

Because of this, designers save space and cost.

Where Sterile Fabrication Needs Linear Actuator

1. Pharmaceutical Packaging and Assembly

Pharmaceutical packaging must stay sterile. Therefore, companies use automated machines. Linear actuators drive filling and sealing systems. They move parts smoothly and accurately. As a result, each package meets quality standards. At the same time, they support aseptic conditions.

2. Medical Device Manufacturing

Medical devices contain small parts.

These parts need careful handling.

Linear actuators control cutting and folding steps.

They also position parts with high accuracy.

Because of this, manufacturers avoid damage.

As a result, production stays consistent and safe.

3. Laboratory Automation

Labs depend on automation for speed and safety. Therefore, precise motion becomes essential. Linear actuators move samples and trays. They open and close equipment doors. For example, they work inside autoclaves and incubators. At the same time, they meet sterilization rules.

4. Aseptic Processing Equipment

Aseptic machines face frequent cleaning.

Because of this, components must stay sealed.

Manufacturers choose stainless steel linear actuators.

They select IP67 or IP69K designs.

As a result, actuators survive washdowns and chemicals.

This improves machine life and safety.

5. Surgical Robot Manufacturing

Surgical robots demand extreme precision. Even small errors can cause problems. Linear electric actuators provide smooth and stable motion. They support accurate robotic arm assembly. Therefore, manufacturers achieve reliable performance.

Key Benefits of Linear Actuator in Sterile Equipment

No Contamination

Electric actuators use no oil.

Therefore, leaks never occur.

Accurate Motion

They move exactly as programmed. As a result, quality stays consistent.

Compact Design

They take less space.

This allows smarter machine layouts.

Washdown Ready

Sealed designs handle harsh cleaning. Because of this, maintenance becomes easier.

Conclusion

Sterile equipment needs clean motion.

It also needs accuracy and reliability.

Linear actuators meet all these needs.

They support automation without contamination.

They also improve efficiency and safety.

Therefore, in pharmaceutical, medical, and lab equipment fabrication, linear electric actuators remain essential components.