In industries where heavy loads are moved daily, lifting and handling systems are essential. From warehouses to assembly lines, these systems reduce physical strain on workers and increase overall efficiency. But what makes modern lifting solutions even more effective is the integration of electric linear actuators. They simplify operations, improve safety, and provide precise control that traditional methods struggle to match.

Why Lifting and Handling Needs Actuators

Traditional lifting systems often depend on hydraulics, pneumatics, or manual effort. While they get the job done, they come with challenges such as:

- High maintenance (oil leaks, air pressure loss)

- Limited precision and repeatability

- Risk of unsafe operation if not monitored carefully

Electric linear actuators solve these issues by offering clean, controlled, and reliable motion for lifting and handling.

How Actuators Simplify Lifting and Handling

1. Precise Positioning

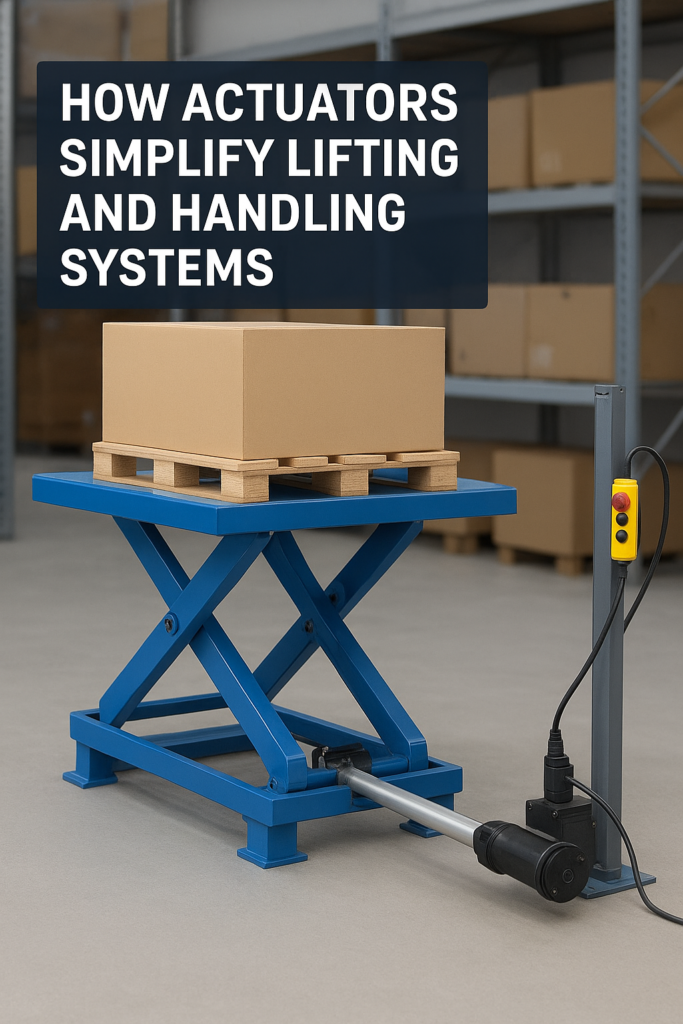

Actuators allow smooth and accurate vertical or horizontal movement. For example, in pallet lifters, they ensure exact placement at the required height.

2. Load Handling Made Easy

With actuators, heavy objects can be lifted or lowered with minimal effort. The push and pull force of electric actuators is ideal for applications where consistent lifting strength is needed.

3. Enhanced Safety

Actuators prevent sudden drops or jerks. They can be fitted with limit switches, overload protection, and sensors to ensure safe handling.

4. Low Maintenance Operation

Unlike hydraulic cylinders, actuators require no oil, pumps, or hoses—resulting in a maintenance-free lifting solution.

5. Automation-Friendly

Electric actuators can be integrated with PLC systems, IoT devices, and smart controls, enabling remote and automated lifting operations.

Applications in Lifting & Handling Systems

- Scissor lifts – for height adjustment in assembly lines

- Material handling carts – for lifting loads in warehouses

- Workstations – adjustable tables and platforms

- Automated storage systems – lifting goods in and out of racks

- Robotic arms – precise lifting and handling of components

Benefits to Industries

- Increased productivity by reducing manual labor

- Improved worker ergonomics and comfort

- Higher accuracy and repeatability in handling tasks

- Lower operational and maintenance costs

- Safer working environment

Conclusion:

Electric linear actuators are transforming lifting and handling systems. Their precision, safety, and easy integration with automation make them a must-have solution for industries aiming for higher efficiency and smarter operations.

Wow, Actuators are doing so many things in material handling.

Offering a diverse selection of Actuators, it caters to both comfortability and innovation. There is a Application for everyone.